10 Reasons Why epoxy resin gets hot! 🔥

In this article, I’m going over why epoxy resin gets hot, what causes it, and what you should know before starting your next project. Epoxy naturally heats up as it cures because of the chemical reaction that takes place when resin and hardener mix. This heat is called an exothermic reaction, and it can get surprisingly intense, especially with larger pours or thicker layers.

I’ve been working on a resin table recently, and I had to be careful not to pour it too deep all at once. It’s easy to forget just how warm resin can get if you’re new to it. Keeping an eye on pour depth really helped me keep everything under control and avoid cracks or yellowing.

Understanding this trait of resin is important so that you don’t ruin your pieces. So, let’s talk about how hot epoxy resin gets and why it heats up.

Main Reasons Why Resin Gets Hot

1. Exothermic Reaction

Resin curing is accompanied by an exothermic reaction, where it transforms from a liquid to a solid state. During this transformation, the chemical bonds within the resin are rearranged, releasing heat. This heat generation is a part of the curing process and is responsible for the warmth you feel when working with resin.

Work in a well-ventilated area to help the dissipation of excess heat and to avoid inhaling potentially harmful fumes. It’s important to note that experiencing some heat during resin curing is normal. If you are working on a large table or pouring deep, you might run into problems with your molds warping. Some people leave fans on but then you risk getting lint or dust in the resin as is cures.

2. Large Mass of Resin

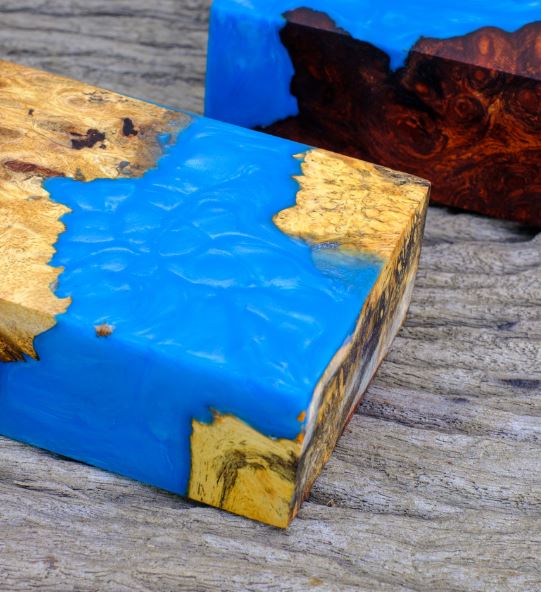

The heat produced during resin curing is directly proportional to the volume of resin used. A larger mass of resin generates more heat as it cures, which can be particularly noticeable.

When working on larger projects, consider dividing the resin pour into multiple layers. Allow each layer to cure partially before adding the next. This is true for resin tables, or deep pours for preserving flowers in resin.

This helps prevents the excessive build-up of heat and minimizes the risk of cracks or deformities forming in your resin creation. It’s also a good practice to follow the manufacturer’s guidelines for maximum pour depths to maintain control over the heat generated.

Some epoxy can only be poured up to 2″ while others can be up to 4″. See this article about the best deep pour epoxy.

3. Quick Curing Resin

Fast curing resins are designed to solidify more quickly, which means they release heat quickly during the curing process. This accelerated curing can result in a more intense perception of heat.

When working with quick cure resins, try to use smaller and shallower molds, which reduces the volume of resin and, consequently, the amount of heat generated.

Closely read the recommended curing times provided by the manufacturer, as these resins can be more sensitive to overheating.

4. Catalyst/Initiator Proportion

An improper ratio of catalyst or initiator to resin can lead to an accelerated curing process and an increase in heat production. This often occurs when too much catalyst is added to the mixture by accident.

To prevent the resin from curing too quickly and generating excess heat, follow the manufacturer’s instructions when mixing your resin. Using the correct proportions of catalyst and resin is very important for controlling the heat generated during curing.

5. High Ambient Temperature

Warm environmental conditions can exacerbate the heat generated during resin curing, making it feel even hotter. High temperatures can amplify the curing.

When working in a warm environment, select a resin with a longer curing time. This choice allows for better control over the curing process and helps mitigate the effects of the external heat.

Consider using a portable fan to keep the air circulating but only do this if you are in a completely clean room free of dust and debris that can fall in to the resin.

6. Curing Accelerators

Certain additives, known as curing accelerators, are used to expedite the curing process. These accelerators, when added to the resin, increase the speed of curing and intensify the heat released during this process.

If you decide to use curing accelerators, exercise caution and adhere strictly to the recommended dosage provided by the manufacturer. These additives can significantly affect the heat generated during curing. I’ve never used anything to make resin cure faster, I have found there’s no need for this. I just let it cure on it’s own.

7. Thick Layers and Deep Molds

Resin poured in thick layers or deep molds has the tendency to trap and retain more heat, which intensifies the curing heat. The accumulated heat may cause problems such as cracking.

When working with deep molds or casting thick layers, pour your resin in thinner layers. By letting each layer to partially cure before adding more resin, you can control the heat generated and reduce the risk of defects. The layering technique helps distribute the heat more evenly throughout the project.

8. Excessive Mixing

Aggressive or extended stirring of the resin mixture can generate additional heat due to the friction created within the mixture. The heat generated can be noticeable during the mixing process. Also see our article about the best epoxy mixing machines that will mix the resin for you.

To prevent excessive heat from stirring, mix your resin gently and don’t go over the time that the instructions say.

9. Reactive Fillers

Some fillers or additives, such as metallic powders or specific pigments, can accelerate the curing process and elevate heat levels during resin curing.

Experiment with small test projects to understand how different fillers impact heat generation in your specific resin formulations.

10. Containment of the resin

When resin is sealed in a closed container, such as a mold or an airtight cover, heat can become trapped and intensify within the enclosed space. When curing resin in molds make sure that that there’s adequate ventilation.

Proper ventilation prevents heat from being trapped and accumulating inside the container. If you need to cover up resin jewelry to prevent dust, be sure there is still ventilation so that there is no overheating.

For those of you who are working with small mold for jewelry and charms, you might want to consider switching to a UV resin which cures under a light.

And f you’re working in an airtight mold, consider demolding your project after it has partially set to release any trapped heat and minimize overheating.

11. Poor Quality of Resin

Using low quality or expired resin can result in various issues, including uneven curing, excessive bubbles, or inconsistent coloration. Poorly manufactured resin often lacks the necessary chemical balance for optimal curing, which can lead to a multitude of problems.

Check that the resin is not expired or past its shelf life. If you suspect you’re working with low quality resin then I wouldn’t even use it. You are going to have so many problems like fast yellowing and bubbles. Some brands don’t even cure properly, I can’t believe they can even sell them.

What to do if resin gets too hot

When resin gets hot during the curing process, take immediate action to prevent issues like cracking or warping. Here is how to cool down epoxy resin when it is getting too hot.

First, if the heat is causing discomfort or you notice the resin becoming too viscous, pause your work to let it cool down.

You can move your project to a cooler area or place it on a heat resistant surface to dissipate excess heat.

Keep in mind that proper ventilation is key to heat dissipation, and following manufacturer guidelines for mixing ratios, curing times, and maximum pour depths.

Thanks for reading about why epoxy resin gets hot. Hope this helps you plan your next project and keep your pours smooth. Feel free to share this article and check back for more resin tips and ideas.