13 Expert Tips: How to remove resin bubbles

Hey resin crafters! We are here to help you remove bubbles from resin with this helpful guide. Ever had your perfect project ruined by annoying bubbles in your resin?

We’ve all been there. But don’t stress – we’ve got some straightforward solutions for you.

In this detailed guide, we’ll be uncovering the techniques to help you achieve flawlessly bubble-free results in your resin projects.

Whether you’re a pro or just starting out, these tips will have you saying goodbye to bubbles and hello to flawless resin creations. Let’s dive in and make your crafting life a whole lot smoother!

We know working with epoxies and UV resin can be challenging, especially when you need to remove bubbles from resin during the pour and after the pour cures.

Remove & prevent bubbles in resin

First, Why does resin get bubbles?

Bubbles form in resin due to a variety of factors inherent to the resin itself, the mixing process, and environmental conditions.

One primary culprit is air trapped during the mixing and pouring stages. Inadequate or improper mixing can introduce pockets of air into the resin mixture.

Additionally, pouring from too great a height can agitate the mixture, incorporating more air. Microbubbles, which are extremely small bubbles often invisible to the naked eye, may also arise from the resin or be introduced during mixing.

External factors such as high humidity can contribute to surface bubbles, appearing on the top layer of the resin. Furthermore, heat generated during the curing process, especially with fast-curing resins, can lead to the formation of bubbles.

Moisture, whether in the air or on surfaces, can react with the resin and create bubbles as well.

Recognizing these various causes is crucial for implementing preventive measures and corrective techniques to achieve a smooth, bubble-free resin finish in crafting projects.

1. Mix resin properly

Achieving a bubble-free resin masterpiece starts with thorough mixing. Take the time to blend your resin and hardener components meticulously.

Use a slow, methodical stirring motion to minimize the incorporation of air during the mixing process.

Vigorous stirring can introduce unwanted air bubbles, so a patient and deliberate approach is key to ensuring a homogeneous mixture. If you are having trouble mixing the resin, check out our article for some resin mixing machines.

2. pour the resin slowly

The pouring stage plays a crucial role in preventing bubbles. Adopt a slow and controlled pouring technique, allowing the resin to flow smoothly onto your project surface.

Rushed or turbulent pouring can agitate the resin, introducing air bubbles in the process. By pouring slowly and with precision, you minimize the risk of trapping air, setting the foundation for a bubble-free finish.

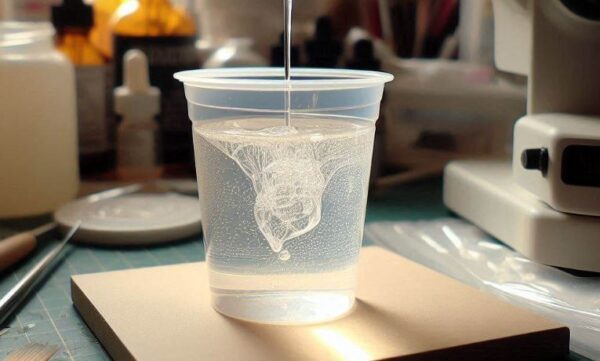

3. Use a Bubble remover or Vacuum Chamber

Remove bubbles from resin before pouring. Take your resin crafting skills up a notch by adding a vacuum chamber to your resin art supplies. Just pop your resin mixture into the bubble remover before pouring to get rid of those tiny microbubbles.

This step is a game-changer, making your resin clearer and decreasing the odds of any pesky imperfections in your finished project.

You can also use a vacuum chamber for larger projects. We have an article on the best pressure pots for resin to help you out.

4. make sure the surface is level

Ensure the surface on which you’re working is level before pouring resin. An uneven or tilted surface can lead to uneven curing and the formation of surface bubbles.

Taking the time to level your work area sets the stage for a smooth and even resin application.

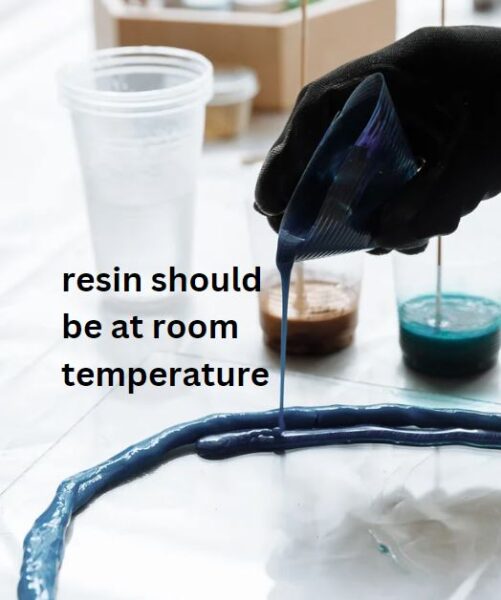

5. Warm Resin To Remove Bubbles

Enhance the flow of your resin mixture by warming it slightly before use so if you have the resin stored in a cold place, you might need to move it to a warmer room before using it.

Warmer resin has reduced viscosity, allowing air bubbles to rise more easily to the surface. So this simple step can really help you remove bubbles from resin.

This simple step facilitates the release of trapped air, contributing to a smoother, bubble-free finish.

If you are using resin in an unheated garage, you may have some troubles with bubbles if your garage is too cold. This can also result in resin that is yellowing.

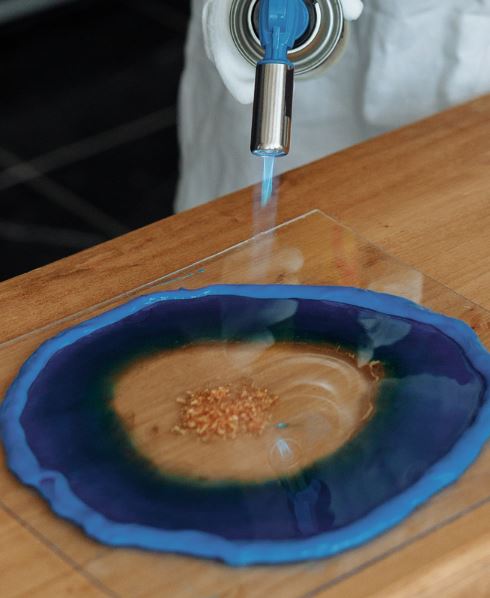

6. use a Heat Gun or Torch

Employ a heat gun or torch strategically to eliminate bubbles on the resin surface. Gently pass the heat source over the resin, keeping it in motion to avoid overheating. This method not only bursts bubbles but also helps in leveling the resin, creating a polished and flawless appearance.

7. Wait Before Torching

Patience is a virtue in resin crafting. Allow the resin to sit briefly after pouring before using a heat gun or torch. This waiting period allows larger bubbles to rise naturally to the surface, making the subsequent torching more effective in achieving a bubble-free finish.

8. Use the proper resin for each project

Minimize the risk of bubbles by using the proper resin for your projects. Fast-curing resins generate more heat during the curing process, potentially leading to bubble formation.

So if you need to do a deep pour, you will need a casting resin. UV resins that cure under a lamp can be used for small items like jewelry.

Here are some of our guides:

Resins to use for covering paintings

Resin for general crafting projects

Best Resins For Stabilizing Wood

And for deep pours and casting, this resin is one of the best.

9. Control the Curing Environment

Maintain a controlled environment for curing. Consistent temperature and low humidity are essential to prevent moisture-related bubble formation. Creating an environment conducive to proper curing ensures the resin can set smoothly without interference from external factors.

10. Pop bubbles that rise

For small surface bubbles that persist after pouring, delicately pop them with a pin or toothpick. Once popped, use a heat source to gently smooth the area, ensuring a seamless finish without compromising the overall integrity of the resin.

11. Cover the resin

Shield your resin project from dust and debris by covering it while it cures. Placing a box or container over the project can prevent contaminants from settling on the resin surface, reducing the likelihood of bubbles caused by foreign particles.

12. Spritzing with Isopropyl Alcohol

Introduce isopropyl alcohol into your resin crafting toolkit for bubble control. Lightly spritzing the resin surface with isopropyl alcohol can help burst bubbles without negatively affecting the resin. Exercise caution with the amount used to avoid any adverse effects on the final result.

13. Inspect after curing

After the resin has fully cured, conduct a thorough inspection of the surface. Address any remaining imperfections by sanding or polishing as needed.

This post-curing step ensures a meticulous final result, free from bubbles and ready to showcase your resin crafting prowess.

Combining these detailed techniques will undoubtedly elevate your ability to achieve bubble-free resin pieces.

Common types of bubbles in resin

Air Bubbles

These are the most typical and occur when air gets trapped in the resin during the mixing or pouring process.

Microbubbles

Tiny bubbles that can be hard to detect with the naked eye, often originating from the resin itself or introduced during the mixing stage.

Surface Bubbles

Bubbles that form on the surface of the resin after pouring. They can result from various factors, including improper mixing, pouring from too high, or environmental conditions like humidity.

Heat-Induced Bubbles

Excessive heat generated during the curing process can lead to bubbles, especially when using fast-curing resins.

Moisture-Related Bubbles

Moisture, whether in the air or on the surfaces being coated, can cause bubbles when it reacts with the resin.

Bubbles From Expired Resin

Expired resin can lead to an increased presence of bubbles, complicating the crafting process.

Bubbles In Resin faq

Let’s go over some questions you might have about bubbles in resin. We’ll try to answer them as best as we can so that your projects turn out as good as possible!

1. Why do bubbles form in my resin?

Bubbles can form in resin due to various factors. Common culprits include insufficient mixing of the resin and hardener, improper pouring techniques, environmental conditions such as high humidity, and the curing process.

Understanding these factors is crucial for implementing effective strategies to prevent or eliminate bubbles in resin projects.

2. How can I prevent bubbles during mixing?

To prevent bubbles during the mixing stage, ensure a thorough and slow mixing process. Use a flat-edge silicone stir stick or wooden one to minimize air incorporation. These measures help create a homogeneous resin blend with minimal bubble formation.

3. Can I use a heat gun to remove bubbles?

Absolutely! A heat gun or torch is a valuable tool for bubble removal. Carefully pass the heat source over the resin surface to burst bubbles, providing a smoother finish.

It’s essential to keep the heat source moving to avoid overheating the resin, which could potentially cause other issues.

4. What role does humidity play in bubble formation?

High humidity levels can contribute to the formation of surface bubbles in resin projects. Maintaining a low-humidity environment during the resin work is essential to minimize the risk of bubbles caused by moisture in the air reacting with the resin.

5. Does resin expiration impact bubble formation?

Yes, expired resin can lead to an increased presence of bubbles, complicating the crafting process. Using fresh, unexpired resin is advisable for achieving optimal results in resin projects. We have a helpful article about how to tell if your resin has expired.

6. How can I eliminate bubbles during the curing process?

o reduce bubbles during the curing process, opt for slower curing resins, control the curing environment by maintaining a consistent temperature, and consider covering the project to prevent dust and debris contamination. These measures contribute to a smoother curing process with fewer imperfections.

7. Can I use a vacuum chamber to remove bubbles?

Absolutely! Using a vacuum chamber is an effective technique to degas resin before pouring.

This process removes microbubbles, enhancing the clarity of the resin and reducing the chances of unwanted imperfections in the final product.

8. Is it normal to see bubbles immediately after pouring resin?

Yes, it’s quite common to observe bubbles immediately after pouring resin. However, various techniques, such as waiting for bubbles to rise, torching the surface, or using a bubble release spray, can address and minimize these initial bubbles.

9. How do I fix bubbles that appear after the resin has cured?

If bubbles appear after the resin has cured, addressing them involves sanding and polishing the cured resin surface. These post-curing steps help achieve a smooth and flawless finish by eliminating any imperfections caused by residual bubbles.

See our guides how to sand epoxy resin and how to fix pits in resin.

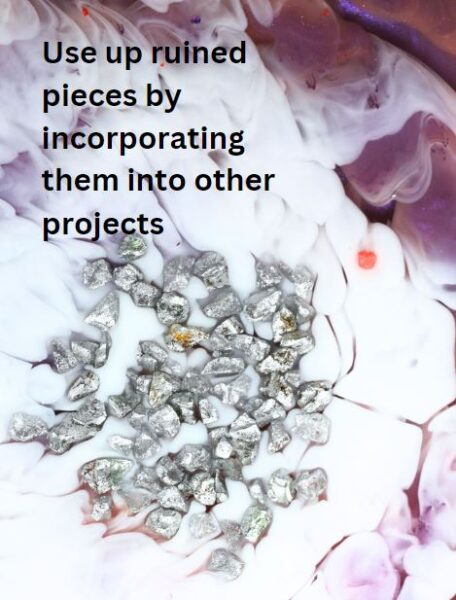

If the bubbles are too deep, there may be nothing to save the project. You can try to use the finished piece by incorporating it into other resin art ideas.

10. Can I reuse resin with bubbles?

While it’s technically possible to reuse resin with minor bubbles, it’s generally recommended to start with fresh resin for crafting projects. Using fresh resin ensures optimal results and minimizes the risk of imperfections in the final product.

If you are a resin artist that makes large abstract pieces, you can use up scraps of resin to give your artwork or other projects a unique look. Try not to waste anything when working with resin as it can be very expensive.

One example is if you just made some resin jewelry and it did not turn out, well you can use those pieces in your resin artwork pours to give them more dimension or for a filler when doing a deep pour that needs extra interest.

In conclusion, we hope this guide on dealing with bubbles in resin has provided you with valuable insights and practical solutions for your crafting endeavors.

Whether you’re a seasoned resin artist or a beginner exploring the world of epoxy creations, conquering bubbles is a crucial step toward achieving flawless results.

Remember, crafting is as much about the journey as it is about the finished product, and each bubble-free creation brings you one step closer to resin mastery.

Happy crafting, and may your future projects be smooth, clear, and utterly bubble-free. Hope you found this guide helpful – happy creating!