How To Seal Paper For Resin: Methods That work

Welcome to our helpful guide on how to seal paper for resin, ensuring that the ink remains vivid and free from unwanted bleeding. You are wondering: Can you put paper in resin? Yes, but there is some important info to know first.

Working with resin and using resin on paper can transform paper creations into long-lasting pieces of art.

However, paper is inherently porous, and without proper preparation, the resin can cause the ink on your paper to smudge or bleed, and completely wreaking your hard work.

In this guide, we will walk you through the step-by-step process on putting paper in resin to preserve the images when working with epoxy resin and UV resin. Yes, you can put resin on paper with the right techniques.

By following these techniques, you’ll be able to create beautiful resin-coated paper art with confidence and precision. Let’s get started to help you seal paper for resin!

How to Seal Paper For Resin

1. Use Proper Sealants before resin

Select a sealant that is compatible with both your paper and the resin you plan to use. Typically, a clear, waterproof sealant or a spray sealant is ideal for paper.

Make sure it dries transparently and sticks well to the paper’s surface, forming a protective barrier against the resin. Here are some sealants that we have tried that work on most papers.

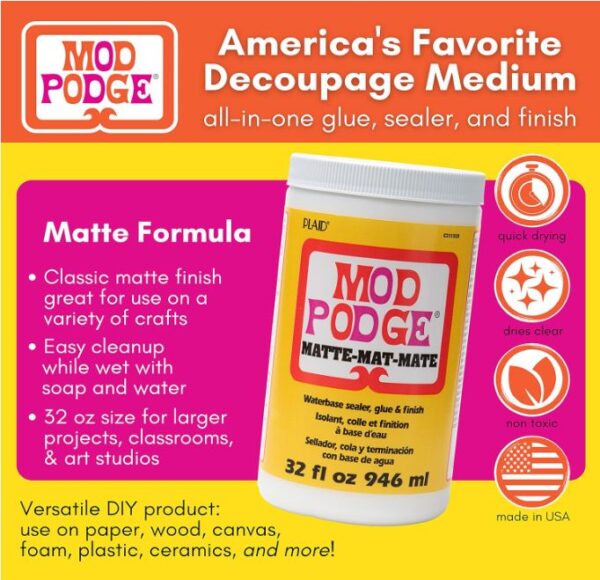

Mod Podge

Mod Podge or decoupage glue is a versatile and widely used method for sealing paper before applying resin in crafting and art projects.

This adhesive is available in various formulas such as matte, gloss, and satin finishes. It is applied in a thin, even layer onto the paper’s surface, to create a protective barrier that prevents ink bleeding and moisture damage.

Mod Podge is known for its transparency. Ensuring that the original design of the paper remains visible. So this is a popular product that’s good to use before coating paper with resin.

Mod Podge dries clear, making it an excellent choice for preserving the integrity of delicate or intricate paper designs.

Crafters appreciate its ease of use, cost-effectiveness, and wide availability, making it a popular choice when preparing paper for resin applications.

To seal the paper with Mod Podge or decoupage glue, gently brush on a thin, even layer, making sure to cover the entire paper surface.

Let it dry thoroughly, and the drying time may vary depending on the thickness of the application, typically taking a few hours.

After drying completely, the paper is effectively sealed and ready for the application of resin.

Mod Podge forms a transparent, protective shield, safeguarding the paper from any potential resin-related issues.

Annie Howes Glamour Seal

Annie Howes Glamour Seal is a specialized sealant designed for sealing paper in resin crafts. This is one of the top products we use to seal pictures or scrapbooking paper for resin.

This versatile sealant is formulated to protect paper from ink bleeding and moisture damage, making it a valuable tool for preserving the integrity of paper elements in your resin projects.

Annie Howes Glamour Seal dries to a clear, glossy finish, enhancing the vibrancy of your paper designs.

Its easy application and quick drying time make it a convenient choice for crafters and artists. This is one of the sealants that we use here often with excellent results.

To use it, simply brush a thin, even layer of Glamour Seal onto the paper, ensuring complete coverage.

Allow the sealant to air dry or use a heat tool for faster drying, typically within 20-30 minutes.

Once the paper is dry and sealed, you can proceed with your resin application.

Annie Howes Glamour Seal dries clear, creating a transparent and protective barrier, preventing ink bleeding and moisture damage.

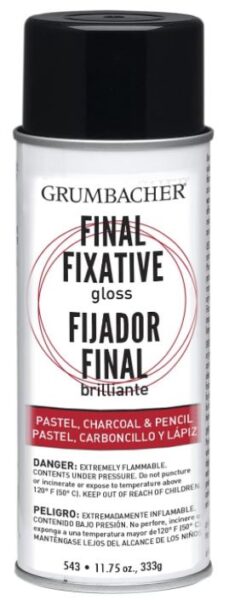

Grumbacher Fixative Spray

Aerosol spray sealants are particularly useful in instances where you need a quick, even, and hassle-free application.

They are to be used to seal paper made with inks, charcoal, pastels and other art materials that could smudge.

Spray sealants excel when sealing paper. When crafting larger pieces like artwork, jewelry boxes or coasters where a brush application might result in uneven coverage, visible brush strokes, or prolonged drying times.

Sprays evenly disperse a fine mist, ensuring complete coverage without the need for manual spreading. This makes them ideal for sealing large or intricate paper designs, as well as for covering three-dimensional objects and projects with intricate textures.

Using Grumbacher spray sealant is a convenient and efficient way to protect your paper for resin projects.

Start by placing your paper on a protected surface to prevent overspray.

Shake the can well, hold it about 10-12 inches away from the paper, and apply the sealant in light, even coats. Make sure to spray in a well-ventilated area and wear a mask if necessary.

Allow each coat to dry for the recommended time, typically 10-15 minutes, before applying additional coats if needed. Once the final coat is dry, your paper is effectively sealed and ready for resin application.

2. Test Compatibility of sealant

Testing the compatibility and transparency of your chosen sealant is a crucial preparatory step when sealing paper for resin projects.

Before committing to your main project, conduct a small-scale test on a scrap piece of paper. This test allows you to assess how the sealant interacts with your specific paper type and whether it maintains the desired transparency and doesn’t run the inks.

Each type of paper and ink can react differently to various sealants, so this trial run helps you identify any issues or incompatibilities early on.

It’s an essential quality control measure that aids in preventing potential problems like ink bleeding, color distortion, or a hazy finish, ultimately leading to more successful and visually pleasing resin creations.

3. Apply Thin, Even Layers

The practice of applying thin, even layers when sealing paper for resin is important for drying and preventing sticky build ups.

When you apply sealant in thin layers, you minimize the risk of over-saturating the paper, which can lead to warping, curling, or a loss of detail in the design.

Thin coats also dry more quickly and evenly, reducing the chances of streaks, uneven coverage, or visible brush marks.

This method offers better control over the sealing process, allowing you to assess the paper’s condition and make any necessary adjustments.

Additionally, building up multiple thin layers rather than applying one thick layer not only maintains the paper’s integrity but also creates a strong, even, and transparent protective barrier that is better suited to withstand the resin application.

4. Seal All Sides of the Paper

Sealing all sides of the paper will help prevent the inks to bleed through on the sides.

It involves applying the sealant not only to the front or primary side of the paper but also to its edges and the reverse side.

This thorough sealing approach prevents any potential moisture, resin, or other external elements from infiltrating the paper’s unprotected edges and compromising its integrity.

If only one side of the paper is sealed, the unsealed edges can be vulnerable to ink bleeding, warping, or moisture damage when resin is applied, leading to unsightly and potentially irreversible flaws in your project.

By sealing all sides of the paper, you create a complete and robust barrier, preserving the paper’s quality, and ensuring that your resin project remains visually stunning and structurally sound.

5. Allow Ample Drying Time

Allowing ample drying time when sealing paper for resin is a critical step that often determines the success of your project. Patience at this stage is key, as rushing the process can lead to issues down the line.

Proper drying time forms a solid, protective layer over the paper, preventing any potential moisture from getting in.

Different sealants have varying drying times, so it’s essential to adhere to the manufacturer’s recommendations.

Rushing through this stage can result in trapped moisture, air bubbles, or incomplete sealing, which could lead to ink bleeding and other imperfections when the resin is applied.

By giving the sealant the time it needs to fully dry, you’re not only preserving your paper but also setting a strong foundation for a successful resin application, resulting in a professional and aesthetically pleasing finished product.

Resin Crafts That Require Paper To Be Sealed

UV or epoxy Jewelry

Resin jewelry often includes paper elements, such as vintage images, delicate designs, or personalized messages.

These paper pieces can be encapsulated in resin to create unique, wearable art. Learn how to make your own DIY resin jewelry with our helpful guide.

However, without sealing the paper, the ink may bleed or smudge when the resin is applied.

Artwork

Artwork frequently incorporates paper cutouts, stencils, or even entire images as a part of the artwork.

To prevent these paper elements from deteriorating or the inks from smudging when resin is poured over them, sealing the paper is essential. This is especially important when using charcoal or pastels.

If you are just learning how to coat artwork with resin we have a guide on the best resins to use for paintings.

Resin Coasters

Coasters featuring paper designs or images are a popular resin craft. These designs are often prone to wear and tear from moisture and the weight of glassware.

Sealing the paper before pouring resin not only protects the paper but also maintains the coasters’ aesthetics over time, creating functional and attractive home décor.

Resin Tumblers

Resin tumblers are stylish and functional drinkware that is meticulously handcrafted by coating a tumbler with layers of epoxy resin. These tumblers are often customized with various paper designs, colors, and embellishments embedded in the resin, resulting in a visually striking and durable piece.

Resin Magnets

Resin magnets often feature decorative paper designs. These magnets are exposed to various environmental factors, such as humidity and handling.

By sealing the paper, you protect it from moisture, dirt, and wear, preserving the quality and appearance of the magnets on your refrigerator or magnetic board.

Resin Photo Frames

Paper photos can be beautifully incorporated into resin frames for a unique and sentimental touch. Sealing the paper photos before adding resin helps prevent color fading, ink running, or any damage from the resin.

This helps so that your cherished memories remain vibrant and protected within the frame.

Resin Jewelry Boxes

Crafters often make resin jewelry boxes with decorative paper inclusions. These boxes can be made by sealing the paper and gluing it to the top of the jewelry box, then taping around the sides to pour the resin on top.

Resin Tabletops

Resin tabletops may feature decorative paper accents that enhance their visual appeal. These tabletops are subject to spills, stains, and the weight of objects.

Sealing the paper in the tabletop not only protects it from damage but also helps with the tabletop’s overall longevity and beauty.

Resin Paperweights

Paper can be sealed when making resin paperweights, preserving the design and ensuring it remains clear and protected.

These paperweights, often placed on desks or used as decorative pieces, benefit from sealing to prevent any deterioration or smudging of the embedded paper.

Resin Decorative Trays

Decorative trays with paper accents add elegance to your décor. Sealing the paper is essential to protect it from stains, moisture, and wear, ensuring that the tray maintains its aesthetic appeal and functional quality for years to come.

Sealing Paper With Resin FAQ’s

Why is it important to seal paper before applying resin?

Sealing paper before applying resin is crucial to prevent the paper from absorbing the resin, which can cause discoloration, warping, and a loss of clarity in the final resin-coated project.

Sealing the paper creates a barrier that not only maintains the paper’s original color and texture but also helps the resin adheres evenly. It will make sure you get a smooth, glossy finish without epoxy resin bubbles or imperfections.

This not only enhances the aesthetic quality of the project but also preserves the integrity of the underlying paper, making it a first step in various crafts like resin art and decoupage.

Can I use any type of paper with resin?

Yes, any paper can be used with resin. but the suitability of paper for use with resin can vary, and there are limitations to consider.

Thicker, non-absorbent papers like glossy photo paper, cardstock, and certain art papers work well with resin as they resist absorption, resulting in a clear finish.

In contrast, thinner or highly absorbent papers, such as newsprint, tissue paper, or standard printer paper, can become transparent, warp, or disintegrate when resin is applied which is why they need to be sealed.

Experimenting with small samples is also a good practice to understand how a specific paper type will interact with resin and chosen sealant.

How long should I wait before applying resin after sealing the paper?

The waiting time before applying resin after sealing the paper can vary depending on the type of sealant you’ve used. In most cases, you should wait until the sealant is completely dry and cured. Here are some general guidelines for common sealants:

- Mod Podge or White Glue (PVA): These typically dry within 15-30 minutes for a single, thin layer. However, it’s a good idea to allow for a few hours for complete drying and curing, especially if you’ve applied multiple layers.

- Acrylic Medium: Acrylic mediums may take a bit longer to dry, often around 1-2 hours. Again, if you’ve applied multiple layers, give it more time.

- Spray Sealants: Spray sealants dry relatively quickly, usually within 15-30 minutes, but check the product’s instructions for specific drying times.

- Wax: Wax can dry quite fast, usually within minutes to an hour.

Check the manufacturer’s recommendations on the specific product you’re using, as drying times can vary based on the brand and environmental conditions.

Additionally, if there’s any doubt, err on the side of caution. Wait longer to make sure that the paper is thoroughly sealed and ready for resin application.

Can I use an alternative to commercial sealants for sealing paper in resin projects?

Yes, you can use alternatives to commercial sealants for sealing paper in resin projects. Some common DIY alternatives include:

Packing Tape:

Packing tape is something you can try. Just make sure when applying the tape there are no trapped air bubbles.

White Glue (PVA):

Dilute white glue with water (about a 1:1 ratio) and apply it to the paper. This creates a homemade decoupage medium that can serve as a sealant.

Acrylic Medium:

You can use acrylic mediums like matte or gloss medium as a sealant. Mix with water and apply it to the paper to seal and protect it.

Wax:

Some crafters use wax, like beeswax or paraffin, to seal paper before applying resin.

In Closing: We hope this answers your questions about if you can resin over paper. The answer is yes! The good news is that with these tips, you can go ahead and put your paper designs into resin including printer paper.

Thank you for taking the time to explore the world of sealing paper for resin with us. We hope that this information has been valuable in enhancing your crafting and resin art endeavors.

Next, check out art article about using resin safely.