7 Best PRESSURE POTS For Epoxy Resin Casting [2026]

Here are the best pressure pots for epoxy resin casting. These are the best vacuum pressure pot chambers for resin casting and wood stabilization. If you’re gearing up for a woodworking project and need a proper pressure chamber for wood stabilization or casting resin, your search ends here. I have been working with resin and epoxy resin for many years and I have some great info for you about the pressure pots to use. The best pressure pots for resin and wood stabilization will give you the perfect conditions for the right pressure to cast for projects like resin wood art.

With these vacuum pressure chambers, you can craft wood products that will give you a crystal clear epoxy finish with no bubbles. It’s one of the tips to working with epoxy resin to create a proper finish. In woodworking and wood stabilization, the best pressure chambers will properly seal and have high end chambers with no leaking of the air.

If you’ve ever pulled a resin piece from a mold and spotted tiny bubbles trapped inside, you’re not alone. You might be working with deep pours, detailed molds, or thicker epoxy that loves to hold air. A pressure pot helps push those bubbles down so your resin cures clear and smooth. It can save you time, resin, and frustration, especially if you sell your pieces or love giving handmade gifts.

What is an epoxy resin pressure pot for?

A resin pressure pot is a sealed container that holds your epoxy resin pieces while they cure under air pressure. The pressure pushes air bubbles down so they are no longer visible in your finished resin cast. This helps your resin art, jewelry, and small tables come out clear and smooth. Resin pressure pots are often used for detailed molds or thicker epoxy where bubbles like to form. If you want cleaner results and fewer flaws, a pressure pot can be a very helpful tool for resin casting.

Best Pressure Pots For Epoxy Resin Casting

1. P PBAUTOS 9 Gallon Chamber

This P PBautos 9 gallon vacuum chamber is made from high strength stainless steel and built to handle resin casting work. It has a tempered glass lid, so you can watch bubbles move while your epoxy resin settles. The two rubber seals help create a tight seal, with one seal on the lid and another on the chamber edge for better pressure control. This setup works well for degassing epoxy resin before pouring into molds. Let your mixed resin sit in the chamber until the bubbling slows down, then release the pressure slowly so the resin does not foam up or spill over the sides.

2. California Air Tools Pressure Pot

This California Air Tools pressure pot is made for day to day use. The rubber feet help keep the pressure pot stable while your resin cures, even on smooth work surfaces. It includes an input connector, regulator, on off ball valve, and a pressure relief valve, so you can control air pressure. It is a great fit for a small business that wants clean, clear resin pieces batch after batch.

3. CAT-365C 5 gallon Pressure Pot

Designed as an upgrade to the model above, the CAT-365C resin casting pressure pot comes with wheels so you can roll it around your workspace instead of lifting it. The internal space measures 12 1/4 inches wide by 14 3/4 inches deep, giving you room for taller molds and layered resin projects. Weighing 35 pounds, the 5 gallon pressure pot can still be moved easily and fits a standard 5 gallon paint pail or bucket. That makes it helpful for batch casting or repeat pours when you are working on several pieces at once.

4. TCP Global 5 Gallon Pressure Pot

Built for epoxy resin casting, the TCP Global 5 gallon pressure pot holds about 20 liters and has a powder coated finish that stands up to regular use. The interior measures 12.3 inches in diameter and 13 inches deep, giving enough space for molds, cups, and small batch projects. It holds constant pressure up to 50 psi, which helps push air bubbles down into the liquid resin as it cures. This steady pressure helps resin pieces come out clear with smoother surfaces and cleaner details. Let your resin sit at pressure for the full cure time listed on your epoxy so bubbles stay compressed until the resin fully hardens.

5. Global 10 Gallon (38 Liters) Pressure Pot

The Global large 10 gallon resin pressure pot gives you lots of room for bigger epoxy resin projects or multiple molds at once. With this size, you can cast larger items like larger wood items, deep pours, oversized coasters, or several jewelry pieces in one batch. It handles thicker resin pours and helps push air bubbles down so your finished pieces come out smooth and clear.

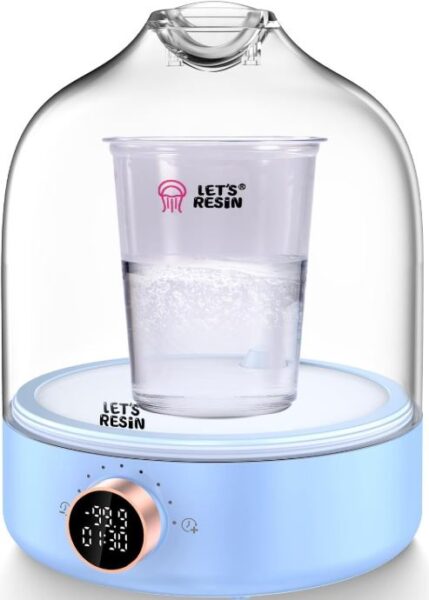

I wanted to give you a couple of options for bubble removers as well. These are a bit different than a pressure pot. A professional pressure pot is used while your resin cures to push air bubbles down and keep them from showing in the finished piece. A bubble remover, or vacuum chamber, is used before you pour the resin to pull bubbles out of the liquid resin itself. It sucks the air out so your resin is mostly bubble free before it goes into molds.

6. Resiners Bubble Remover

I’ve used the Resiners products many times over the years, and I really like their quality. This machine pulls bubbles out of epoxy so your pieces come out smooth and clear. It has enough room for small to medium batches. You can use it for jewelry, coasters, or layered resin projects. Once you try it, you’ll see how much cleaner your resin looks.

7. Let’s Resin Bubble Chamber

The Let’s Resin Bubble Remover is one of the top sellers for a reason. I’ve used their resin to make DIY epoxy tables and they have a full shop of epoxy products. This machine makes getting bubbles out quick and easy. It works great for small to medium batches and helps your resin come out smooth and clear, which is especially helpful for bigger projects like tabletops or layered pours.

Tips For Choosing A pressure Pot For Resin

Pick The Best Size

Pick a pressure pot that fits the molds or projects you usually work on. Smaller pressure pots are great for jewelry, coasters, or small resin pieces. Bigger pots work well if you cast large coasters, or multiple pieces at once. Think about the space you have in your studio and how much resin you normally pour, so your pressure pot is the right fit for your projects. Measure your tallest mold and your largest resin container before buying to make sure everything fits comfortably inside.

Operating Pressure

Look at the maximum pressure your resin pressure pot can hold and choose one that matches your resin needs. Most epoxy resin works well at 40 to 60 psi, which helps push bubbles down without damaging your molds. A pressure regulator and relief valve make it easier to control the pressure safely and keep your pieces looking smooth. This will help common problems like dimples in resin.

Material and Durability

Look for pressure pots constructed from sturdy and durable materials, such as heavy gauge steel. A durable, powder-coated finish can also make cleanup easier.

Safety Features

Choose a pressure pot that has safety parts like a pressure relief valve, regulator, and a secure lid lock. These help you keep the air pressure where it should be and give you a way to let pressure out safely when your resin is done curing. Always check seals and valves before you start, and wear eye protection when you’re pressurizing your resin work.

Mobility

Think about how easy it is to move your pressure pot around your studio or work area. Some pressure pots have wheels or built in handles that make them easier to roll or carry, which is nice if you move your gear often. If your pressure pot doesn’t have wheels, set it on a cart or stand with casters so you can roll it out of the way when you’re done. Just make sure it’s totally secure.

FAQ about resin pressure pots

Why do I need a pressure pot for resin?

A pressure pot helps push air bubbles down while your resin cures, giving you clearer, smoother pieces. It’s especially useful for deep pours, detailed molds, or thicker epoxy that traps bubbles. Using a pressure pot saves time and makes your resin art or larger projects look cleaner and more polished.

Read this guide: How to fix resin that is not curing.

How do I clean a pressure pot for resin casting?

Start by wiping out any leftover resin with a resin wipe while it’s still soft. For cured resin, gently scrape it off with a plastic or silicone tool so you don’t scratch the pot. Wash the pot with warm soapy water, rinse well, and dry completely before storing to keep seals and metal parts in good shape. Don’t use harsh chemicals that could damage the rubber seals, and check seals regularly for wear to keep your pressure pot working properly.

Can I use any type of resin in a pressure pot?

Not all resins work the same in a pressure pot, so it’s important to check with the brand you’re using. Some thicker or slower curing resins may need different pressure levels or times, and others might react differently under pressure.

How do I choose the right size of a pressure pot for my resin casting projects?

The size of the pressure pot should be determined by the scale and quantity of your resin casting projects. Larger pots are for bigger or multiple castings, while smaller pots are better for smaller projects like jewelry or DIY coasters. Measure your molds or project dimensions to select the right pressure pot. If you are looking for smaller ones for crafts, here is a list of the best bubble remover machines for resin crafts.

What safety precautions should I take?

Always wear eye protection and gloves when working with a pressure pot to protect yourself from splashes or spills. Make sure the lid is securely sealed and the pressure relief valve is working before turning on the air. Keep the pot on a stable, flat surface, and never leave it unattended while under pressure. Double check seals and valves before each use, and release pressure slowly when your resin is finished curing to keep everything safe. Always follow the manufacturers directions.

Read this guide about working with resin safely.

Using a pressure pot can really help your resin projects come out smooth, clear, and professional looking. From small molds to larger pours, the right pressure pot makes a big difference in your results. If you found these tips and pressure pot recommendations helpful, share this article with your friends or fellow resin makers.