How to make resin magnets

Welcome to our guide on how to make your very own resin magnets. Yes, you can make your own custom magnets using epoxy resin or UV resin. And it’s actually pretty easy to do.

Making resin magnets is fully customizable. And you can incorporate cool things like dried flowers, mica powders, glitters for resin and colorants.

In this blog post, we’ll guide you through the steps and give you some tips to help you create one-of-a-kind pieces that you can make for yourself or give away as gifts.

Get your resin supplies ready and let’s make some cool magnets. By the end of this DIY, you will have a better idea on how to make all kinds of beautiful magnets.

How to Make Resin Magnets

1. Getting Started with DIY Magnets

Epoxy resin or UV resin is what you will be using for this craft. It’s what you use to make the magnets super shiny. This is what you will use for the carrier to add things like dried flowers or glow in the dark powders to tiny polymer clay inclusions.

This resin magnet below was made with resin & glitter. Then it was poured into a magnet pendant tray. So easy!

In this guide, you’ll learn about the types of resin available, including epoxy and UV resin, and how to select the one that suits your project.

2. Choosing the Right Resin for Magnets

Selecting the appropriate type of resin is a personal decision. I’ve used both epoxy resin as well as UV resin to make small things like magnets so you can totally use either.

The first step in making magnets with resin is to understand the types of resin available and the unique characteristics each one has. Because the magnets are pretty small as far as resin projects go, epoxy resin and UV resin are the two main options.

Epoxy resin is a two part resin that you need to mix. It’s good for larger pieces or for those who are going to be selling and need to make a whole bunch at once.

It will give your magnets a glossy, glass-like finish and is fantastic for embedding objects into the magnets. Craft Resin is a great resin to try for magnets. You can buy these smaller sample sizes to try out before getting the jugs.

On the other hand, UV resin is a quick-curing option that’s perfect for small magnets.

It cures when exposed to UV light, so if you are a beginner, you might find this more easy to use than the epoxy resin. But again, it’s just a matter of preference. Both can be used for this type of craft.

Factor in the pot time, which is the working time you have before the resin begins to harden. Epoxy resin will give you about a 30 minute working time depending on the brand, UV resin is going to harden up almost immediately in about 1-2 minutes.

Another key element to consider is the clarity of the resin. Some resins may have a slight yellowing or may not be entirely crystal clear. So the ones we recommend will be the clear kind.

Clarity is important, especially when working with translucent colorants in your magnets, as it affects the final appearance of your pieces. Check out our guide on how to use resin properly before starting out.

Quick Tips For Choosing Resin For Magnets

- Purchase resin that is crystal clear like the choices above.

- Use UV resin for smaller magnets as it will cure fast when it’s placed under a UV light.

- Choose epoxy resin that doesn’t create a lot of bubbles when stirring.

- Thicker resins will hold embedded objects better.

- Look for a non yellowing resin.

3. how to make Resin Magnets

Gather Your Supplies:

Collect the necessary materials, including epoxy or UV resin, magnet molds, inclusions like glitters or golds for resin, colorants, mixing cups, stirring sticks, a heat gun or torch and resin safety equipment.

You will also need raw earth magnets to glue onto the back of your piece. So if you are making a magnet that is clear, keep in mind that you are going to see the magnet on the back.

If this bothers you, make sure the magnet is opaque in color, or you can try making magnets with jewelry pendant trays which looks really pretty,

Prepare Your Workspace:

Set up a clean, organized, and well-ventilated workspace with a flat surface. Cover your work area with a disposable tablecloth or plastic sheet to catch any drips or spills.

Measure and Mix the Resin:

Follow the manufacturer’s instructions to measure and mix the resin and hardener components in the designated mixing cups. Typically, this involves using a 1:1 ratio by volume or weight. If using UV resin, you can skip this step since it is already pre-mixed.

Add Colorants (Optional):

If you want to color your resin, add the color or dye in small amounts. Mix well until you achieve your desired shade. Just don’t add to much or your resin might not cure properly. See our guide on some of the most common resin problems.

Pour Resin into Molds:

Carefully pour the mixed resin into your chosen molds. Fill the molds to about halfway if adding things like flowers. If you just want it clear, then fill it to the top.

Add Inclusions:

If you’re embedding objects or inclusions, use tweezers or a toothpick to arrange them within the resin. Adjust their position until you like the placements.

Remove Air Bubbles:

Use a heat gun or torch to pass over the resin’s surface to release any remaining air bubbles. Be gentle and maintain a safe distance to avoid overheating the resin. You don’t want it to get scorched.

Curing Time:

Allow the resin to cure as per the manufacturer’s recommendations. This usually involves letting it sit undisturbed for several hours or overnight if using epoxy resin. Make sure that it’s covered up so that lint or hair doesn’t get into it.

When using UV resin, it will be cured within a few minutes.

Demold and Finish:

Once the resin is fully cured and hardened, gently demold your magnets. You may need to flex silicone molds to release the items. Here’s an article about how to demold resin molds.

After demolding, you can sand, polish, and finish your magnet to make it even more glossy, or leave as is.

To learn more about finishing with sanding check out our guide about sanding epoxy resin.

Now attach a raw earth magnet to the back. The best way to attach the magnet is with E-6000. Glue the magnet and once it has set, carefully add a small amount of UV resin for extra strength and cure it.

Raw earth magnets come in many sizes and strengths

With these basic steps and some practice, you can create beautiful DIY fridge magnets. Remember to follow safety guidelines, be patient, and experiment with different designs and techniques to develop your skills and style.

4. Supplies for Resin Magnets

Creating homemade magnets is such a fun craft and you will need the right tools and supplies. Here are some of the basic things you will need to make them.

Resin

Resin is the core material for your magnets. Depending on your project, you can choose between epoxy resin and UV resin, each with its own curing process and characteristics.

Safety Supplies

Safety Gear & resin safety should be your top priority when working with resin. Always wear proper nitrile gloves, a well-ventilated mask, and protective eyewear to avoid skin contact and inhaling fumes.

Magnets

Raw earth magnets are the best to use for this type of craft.

Inclusions & Embeds

Collect and prepare the inclusions for your magnets, which can include dried flowers, tiny charms, glitter, or other decorative elements.

Measuring Tools:

Use digital scales or graduated mixing cups to measure the resin and hardener accurately.

Mixing Containers:

You’ll need containers for measuring and mixing the resin. The best mixing containers are silicone as they can be reused many times to reduce waste and money.

Silicone stirring sticks are also needed for thoroughly mixing the resin and any added pigments or dyes.

Pigments and Dyes:

If you wish to add color to your resin, various pigments and dyes are available. See our guide about the best colorants for resin to use.

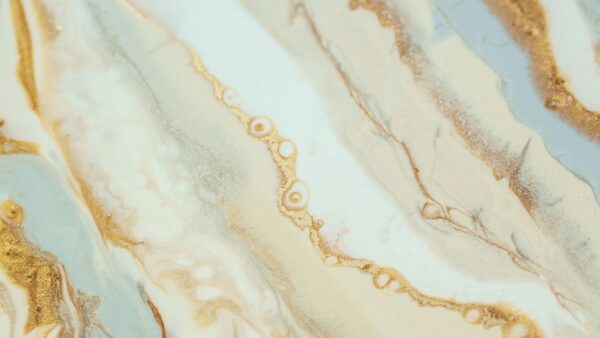

Alcohol Inks for resin Magnets:

Alcohol inks are a popular choice for adding color. They come in a ton of colors and are fantastic for creating abstract or marbled effects.

Alcohol inks are best applied in small drops or streaks onto the surface of the resin, allowing them to spread and blend organically. They are super fun to use, I love using these for not only resin, but for other crafts too.

Air Bubble Removers

Use a Heat Gun or Torch to remove air bubbles for a smooth finish. A heat gun or torch helps to eliminate bubbles that form during the mixing process. You can also use a resin bubble remover machine.

Polishing Supplies:

Once your resin pieces have cured, you might want to refine the surface and get an even higher gloss finish. See our guide on how to polish epoxy resin.

5. Safety Precautions When Working with Resin

When working with resin, it’s essential to prioritize safety: work in a well-ventilated area and wear a respirator to avoid inhaling fumes, use gloves and safety goggles to protect your skin and eyes.

We consider resin an adult craft and do not recommend children using it.

Have a dedicated workspace, avoid direct contact with resin on your skin, and handle chemicals with care.

Read and follow the manufacturer’s instructions for the specific resin you’re using for safe handling, proper disposal of any resin waste, and compliance with safety guidelines.

6. Working with Molds

Understanding how to work with molds is key to crafting unique shapes and designs for resin magnets.

Mold Selection:

The first step in working with molds is choosing the right one for your project. Silicone molds are popular for their flexibility, ease of use, and ability to produce intricate details.

They come in various shapes and sizes, including those designed specifically for magnets because they are not too deep.

Additionally, you can create your custom molds using silicone mold kits or find items like ice cube trays or silicone baking molds to explore unique shapes.

7. Adding Inclusions:

If your design calls for embedded items such as flowers, beads, or charms, decide if you want to add them to the mold before the resin, or sprinkling them on top of the resin. It will depend on what you are using.

Fine glittery elements will sit more on top, and heavy embeds will settle near the bottom.

8. Common Resin Magnet Mistakes

Making homemade magnets can be a rewarding and creative project to try, but it’s also prone to common mistakes that can be frustrating for beginners.

To help you avoid these pitfalls, here are some tips to for a smoother and more successful resin making session.

Read and Follow Instructions

- Mistake: Ignoring or misinterpreting the manufacturer’s instructions for your chosen resin.

- Solution: Carefully read and follow the instructions provided with your resin, including the recommended mixing ratios, curing times, and safety precautions.

Measure Accurately:

- Mistake: Inaccurate measurements when mixing resin components.

- Solution: Use digital scales or graduated measuring cups for precise measurements. Follow the recommended ratios for your resin.

Avoiding Bubbles:

- Mistake: Failing to remove air bubbles in the resin and mixing air into the resin.

- Solution: Use a heat gun or a torch to gently pass over the resin surface to release air bubbles. Keep the heat source moving to prevent overheating. Do not mix any air into the resin while mixing.

Layering and Timing:

- Mistake: Pouring resin layers too quickly without allowing sufficient curing time, which can cause layers to blend or deform.

- Solution: Allow each resin layer to partially cure before adding the next layer. Follow the manufacturer’s recommendations for timing.

Inclusion Arrangement:

- Mistake: Displacing or shifting embedded objects while pouring resin.

- Solution: Plan your inclusion arrangement carefully and use tweezers or a toothpick to adjust their position before the resin sets.

Mixing Coloring Agents:

- Mistake: Overmixing pigments and dyes, leading to undesirable color outcomes or excessive air bubbles. Adding too much colorants can cause the resin to seize up.

- Solution: Stir coloring agents gently and avoid overmixing. Take time to experiment with color combinations to achieve your desired effects.

Safety Precautions:

- Mistake: Neglecting safety gear like gloves and eye protection, resulting in skin contact or eye exposure to resin.

- Solution: Always wear appropriate personal protective equipment when working with resin, and work in a well-ventilated area.

Demolding Carefully:

- Mistake: Rushing the demolding process, which can damage the resin or the mold.

- Solution: Take your time when demolding, gently flexing silicone molds and using a soft touch to avoid wreaking your magnets.

Practice and Patience:

- Mistake: Expecting perfection from the start.

- Solution: Understand that resin making is a craft that improves with practice. Don’t be discouraged by early mistakes. Make your magnets in small batches at first.

9. Do resin Magnets turn yellow?

Yes, sometimes magnets can start to turn yellow over time. Here’s some things to take note of especially if you are going to be selling.

UV Exposure: Exposure to ultraviolet (UV) light, such as sunlight or indoor fluorescent lighting, is a common factor that can cause resin to yellow. Over time, UV rays can initiate a chemical reaction in the resin that results in a yellowish tint.

Quality of Resin: The quality of the resin you use can also impact its resistance to yellowing. Higher-quality resins are often formulated to resist yellowing and maintain clarity over an extended period.

Pigments and Additives: The type and quality of pigments, dyes, or other additives used in resin can influence the likelihood of yellowing. Some pigments and dyes are more stable and less prone to fading or changing color.

Minimize Yellowing In Resin

- Use UV-resistant resin if you’re concerned about yellowing.

- Avoid excessive heat, as high temperatures can also accelerate yellowing in some resins.

- Consider using pigments and additives that are known for their resistance to fading and yellowing.

See our guide: Why is my epoxy resin turning yellow.

It’s important to note that even with precautions, epoxy resin may still yellow to some extent over a long period.

10. Do you need a UV light?

UV resin, as the name suggests, requires exposure to ultraviolet (UV) light to cure. This type of resin is not activated until it is exposed to UV light, usually from a UV lamp or sunlight.

The choice of resin (epoxy or UV) largely depends on your preferences, the specific techniques you want to use, and the desired curing times. If you don’t want to use a light, then epoxy resin must be used.

We hope this helped you to make some beautiful magnets. Happy crafting!